DW Logistics – Packaging Specialists

- Connector.

Manufacturing & Packaging Process

Identifying what type of packaging suits your manufacturing process the best is vital. Does your packaging fulfill its function in terms of assisting your filling or manufacturing lines and minimizing damages?

- Connector.

Warehousing and Distribution

Products that fit onto pallet and shelf is first price! Damages results in returns costs as well as lost sales. Products that does not fit onto pallets increases pallet rental, warehousing and distribution costs!

- Connector.

Retail Distribution

Understanding how the retail chain distribution process works is vital to product and packaging design. Attention should be given to unit size and weight as well as how much protection the secondary pack can provide the primary packs during the picking process. Best before dates that are clearly visible on secondary and primary packs are vital. Packs that are easily identified are damaged less.

- Connector.

Merchandising

Shelf optimization saves costs and reduces damages. Secondary packaging that doubles as retail ready packaging saves merchandising effort and costs.

About Us

With 32 years of experience in the South African packaging industries, we are able to assist customers in choosing cost effective packaging that will not only protect the contents, but also play a role in reducing damages and the costs associated with it!

Packaging is a very misunderstood and costly part of the logistical cost to get product from supplier floor to retailer shelf. The supply chain has evolved and yet packaging has not kept up with these trends. Packaging suppliers attempts to reduce cost by light weighting or eliminating some packaging materials. This is quite evident in the numbers of damages and returns.

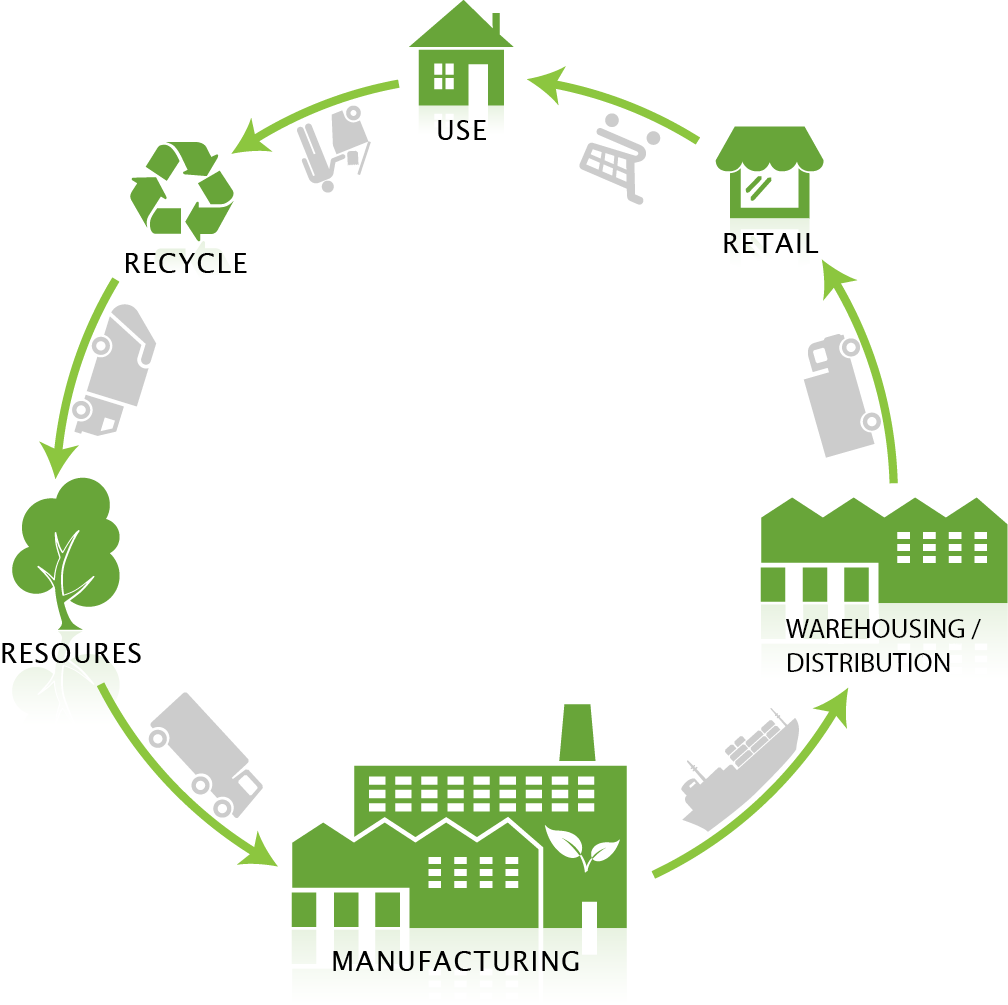

The role of packaging starts when a product is manufactured and has to be placed into a container or bag before distribution. The design, material and size play a major role in manufacturing speeds, pallet efficiencies, distribution and warehouse efficiencies. The role of packaging does not end when the product has been placed into it and distributed to customer warehouse. It also has a huge role to play in the identification as well as protection of caseloads or units during the picking process before distributing it to stores.

The idea is not only to consult, but also to pass on knowledge to customer packaging technologists in the process. Technologists designs packaging that “looks” good, but are not able to perform due to the fact that the whole distribution chain is not taken into account. What is vital is that packaging, at the end of its lifecycle, is recycled / discarded of in a responsible manner to ensure a better carbon footprint.

Reverse logistics is a service that brings packaging back to the supplier for re-use. Cycles of up to four times with huge cost savings can be achieved. Reverse logistics deals with the handling, collection, collating and distribution of packaging materials from the end-user back to the supplier.

7 deadly reasons for damages / returns to occur?

- Connector.

Incorrect packaging

• Incorrect packaging specification in terms of material, design and size.

- Connector.

Incorrect application

• Incorrect application of design – fit for purpose etc.

- Connector.

Environmental exposure

• Environmental exposure to moisture or direct heat.

- Connector.

Warehousing practices

• Warehousing practices as far as procedures are concerned.

- Connector.

Inadequate identification

• Inadequate identification of product on packaging.

- Connector.

Handling of product

• Handling of product by the picker, merchandizer or customer.

- Connector.

Damages not reported

• Damages not reported back to suppliers accurately to rectify matters.

WHAT WE OFFER

Packaging Materials

Packaging Methods

Warehousing

- Pallets stacked with the incorrect stacking patterns or packed too high result in the bottom row collapsing as it cannot bear the weight.

- Wrong stacking patterns are used resulting in wasted space on pallets and in turn warehouse space.

- Incorrect stretch wrapping material and practices making it difficult to identify product or loads shifting during transportation and pallet loads “leaning”.

Packaging Logistics